Quality Assurance & Calibration Department

Bright Steels Limited are delighted that the refurbishment of our quality assurance and calibration department has been completed.

The upgrade to this department has created a working space for our three Jones & Shipman cylindrical grinders which are used for the regrinding of our die segments.

We also have a temperature-controlled calibration room including two shadowgraph machines, one of which is linked to our fusion software.

Additional equipment includes both Brinell and Rockwell hardness testing machines and an administration office.

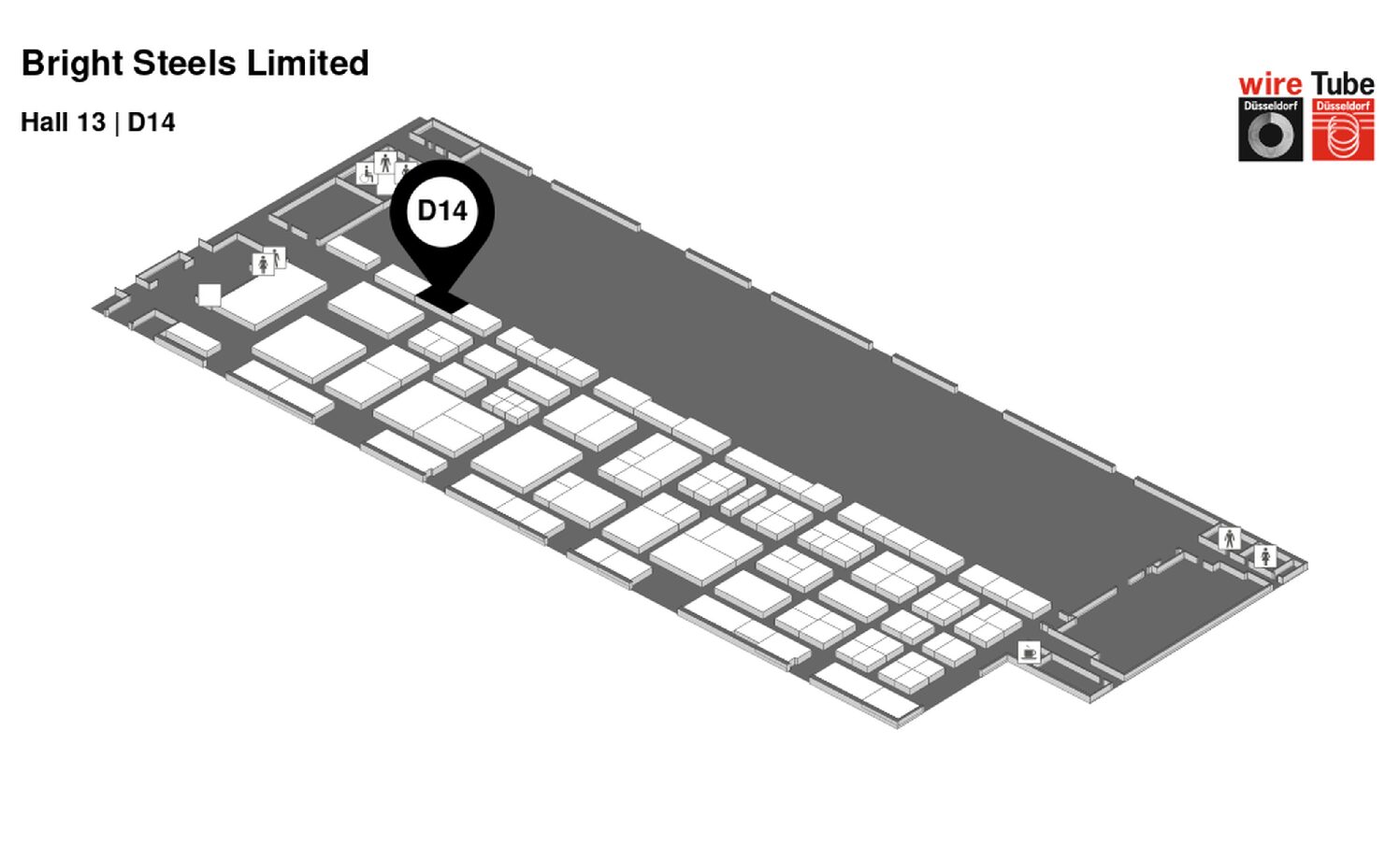

Tube & Wire Exhibition 2024

Bright Steels Limited are pleased to announce that we are exhibiting at the International Tube & Wire Exhibition in Dusseldorf from 15th to 19th April 2024.

We will be delighted to welcome you to visit our stand to view our product range, discuss business and to enjoy a drink together.

The stand location is in hall 13, number D14 and is a joint stand with our European partner and distributor of freecutting steels, PKS GmbH, Peter Kördell Stahlhandel whose warehouse is in Mettmann, Germany.

Please follow this link for more information regarding the exhibition https://www.wire-tradefair.com/.

Bay 8 tubs

Bright Steels Limited have installed four new 316 stainless steel dipping tanks each holding 7500 litres of bonderising solution.

The main aims for the project are to reduce maintenance schedules, immersion times and lowering the working temperatures to reduce our energy consumption and carbon footprint.

The system is controlled by a PLC closed loop system, with additional turbine motors for electrical energy harvesting.

50 Years of Service

Congratulations are extended to Paul Chouler and David Paterson who commence their 50th year of employment with Bright Steels Ltd.

We are honored to have many employees who have contributed to the success of our company over a great number of years and we congratulate Paul and David as to achieve 50 years is a proud milestone.

Carbon Footprint

Bright Steels Limited have installed a 62kW solar PV system which includes 162 solar panels and a 50kW SMA inverter. The system will generate over 45,000kWh of electricity every year whilst saving 16 tonnes of CO2.

We have a passion for protecting the environment and are proud of the company’s efforts to reduce our carbon footprint. The company uses an electric vehicle to move steel around the main production facility, we have paperless documentation with our suppliers and customers, plus we now have two electric company vehicles and have installed LED lighting throughout every area of the company.

Wanting to reduce Bright Steel’s carbon footprint even further, we have invested in solar to power the company’s offices and main production facility during the working hours of the day, with surplus energy sold back to the grid.

Coronavirus Statement

Established in 1919, Bright Steels Limited has always made the health, safety and wellbeing of our employees a priority and as such we take the coronavirus pandemic extremely seriously.

In response, we have implemented a number of procedures throughout the company to best safeguard our employees, their families, our operations and therefore protect the NHS and our community.

We will continue to follow and implement the Government’s Health advice as a minimum standard and to operate our company in a safe manner that ensures the quality of our product and service to customer’s remains delivered as usual.

Existing protocols established with our supply chain partners have been reviewed to ensure continuity of supply for essential raw materials and supplies and we have planned for all eventualities to ensure the safe and continued operation of our business.

We appreciate that this is an evolving situation and will continue to take the necessary steps to practicably safeguard the reliability of our services and health of our colleagues.

Office refurbishment

A major refurbishment to our offices is now complete. On the exterior of the building we have painted the fascia’s and installed new signage. Internally new ceilings have been installed along with new LED lighting, a new smoke alarm system and a new heating and air conditioning system plus new flooring as well as furniture and upgrades to the kitchens and bathrooms including disabled facilities.

LED is now installed around the office drive and new lighting installed in car parking area.

Zak Holmes - level 3 engineering apprenticeship

Bright Steels are proud to announce that Zak Holmes has completed his level 3 engineering apprenticeship.

In recognition of his hard work and achievements he was presented a Hugo Boss watch by Paul Chouler.

We would like to wish Zak good luck on the next stage of his career with Bright Steels Ltd.

Our thanks are extended to Derwent Training Association who have supported Zak through his apprenticeship.

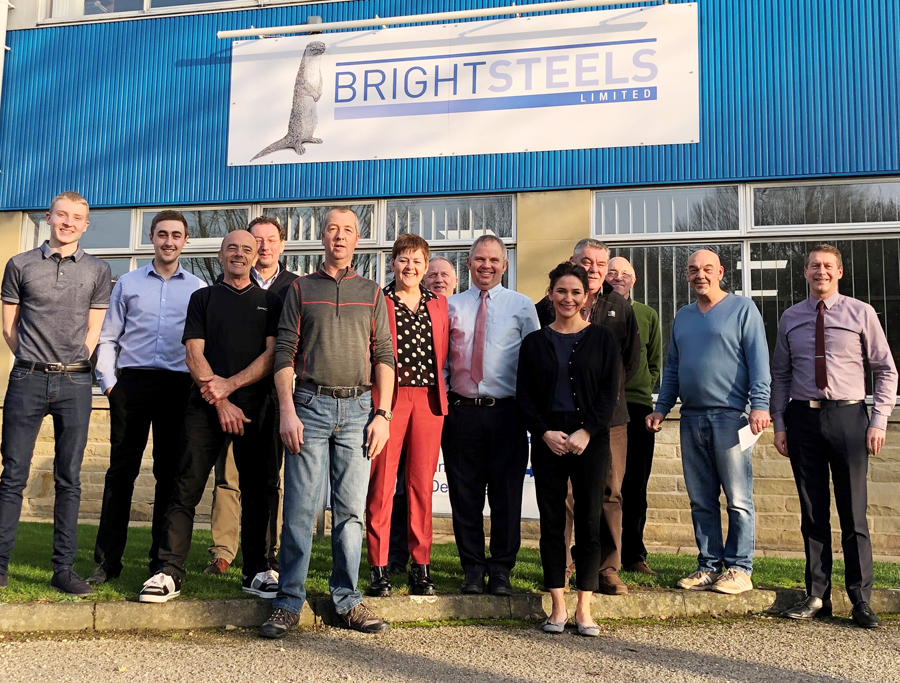

Bright Steels Ltd Centenary Day

On 24th September 2019 all staff celebrated Bright Steels Limited “Centenary Day” with a social reception in the main offices.

In August employees and their families enjoyed the summer sunshine with a family day at The Old Lodge Hotel in Malton and the celebrations continued on the evening of 13th September with a dinner dance hosted at Sandburn Hall near York.

100 years as a private company owned by The Chouler family is a proud achievement reflected by the celebrations of 2019.

Management Promotions

Three members of our senior management team have been promoted to the position of Director in recognition of their contribution to the growth and continued success of Bright Steels Ltd.

From left to right, Chris Cattle – Works Director, Steve Everitt – Sales Director and Paul Stead – Finance Director.

Chris joined the company on 1st February 1988, Steve on 3rd October 1983 and Paul on 31st October 1977.

Their appointments strengthen the structure of the company as it continues to invest and build for the future.

New Sawing System

Bright Steels Ltd have installed a new sawing system to increase capacity for the cutting of bundles of flat or square bars to an exact tolerance.

The precision band saw is complemented with a full infeed and outfeed material handling system.

Bright Steels Sponsor Squash Club

Bright Steels Ltd are delighted to announce their sponsorship of the Junior Section at Malton and Norton Squash Club.

A number of the juniors can be seen wearing their new shirts, as provided by the company alongside Steve Everitt, Sales Director who contributes towards their coaching.

Bright Steels -100 years of business!

The history of Bright Steels Limited began in the year 1919 when the company was established by Mr Cris Chouler.

From the beginning we have been a family business and to this day we continue that policy, not only in the ownership of the company but also with mothers, fathers, sons and daughters employed in both works and administration.

We employ approximately 80 people including our own skilled tradesman, engineers, electricians, joiners and tool room staff. As far as possible we are a self-contained unit of professional people.

Bright Steels Limited specialises in the production and stockholding of bright cold drawn flat bars, squares, hexagons and alloy rounds in addition to the manufacture of special shapes produced according to customer’s drawings.

Reaching 100 years of business as a private, family owned company is an achievement that deserves to be celebrated. To recognise past accomplishments with pride and look to the future with vision.

Honouring our employees, past and present who are central to the continued success of Bright Steels Ltd.

The mission of our 100th anniversary is to celebrate by reflecting on our proud history as a family owned company, and more importantly focusing on our future success.

Long service achievements at Bright Steels Limited

Chris Cook - level 3 advanced electrical apprenticeship

Bright Steels are proud to announce that Chris Cook has passed his level 3 advanced electrical apprenticeship having completed the 4 year course in only 3 years.

In recognition of his hard work and achievements he was presented an engraved Skagen watch by Paul & Marianne Chouler.

We would like to wish Chris good luck on the next stage of his NVQ4 and HND education.

Our thanks are extended to Derwent Training Association who have supported Chris and will continue to do so over the coming years.

ISO Certification

Bright Steels Limited have successfully completed transition to the 2015 revision of the Quality Management System standard ISO 9001 following assessment by BSI, continuing our commitment to quality of both product and service to all our customers throughout the world.

The scope of our Quality Management System is: The manufacture and supply of a range of bright, cold drawn and machined steel sections.

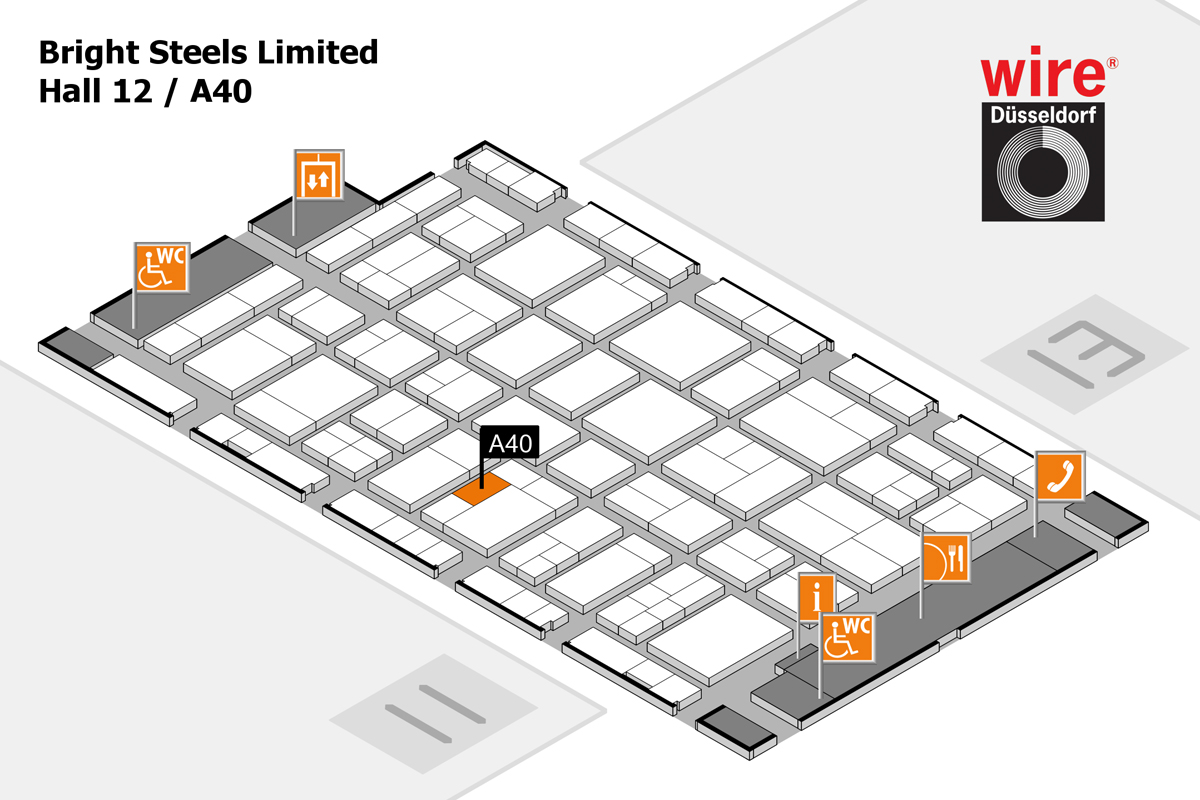

Tube & Wire Exhibition 2018

Bright Steels Limited are pleased to advise that we are again exhibiting at the International Tube & Wire Exhibition in Dusseldorf from 16th – 20th April 2018. We would be delighted to see you visit our stand to view our product range, discuss business and enjoy a drink together. Our stand is located in hall 12, number A40 and is a joint stand with our European partner and distributor for freecutting steels, PKS GmbH, Peter Kördell Stahlhandel who are located in Mettmann, Germany. For full info about the show, please click here: https://www.wire-tradefair.com/

Derwent Training Association 2017 awards night

Congratulations to Chris Cook on winning the 2nd year Electrical/Maintenance Highly Commended Award.

Multi-roll profile straightening machine

Bright Steels Limited have installed a new multi-roll profile straightening machine with feeding table and entry guide, oil spray system, delivery table and stacking system.

This is a dedicated off line processing machine for a dedicated range of sizes where bar straightness is critical and will provide greater capacity for our customers.

Ensuring speedy access to a defibrillator can save lives

It is abundantly clear that speedy access to a defibrillator would have the potential to make the difference between life and death, therefore Bright Steels Limited have installed defibrillators into the main production works, warehouse facility and offices.

The HeartSine Samaritan PAD is a user-friendly, semi-automatic defibrillator and features a clear interface for simple visual instructions throughout. To help the rescuer stay calm under pressure, the defibrillator provides step-by-step audible prompts and sounds a metronome for CPR speed guidance.

Quality Manger retires after 43 years at Bright Steels Limited

Peter Bogg, Quality Manager has retired after 43 years with the company, however his skills are to be retained as he will be working on a part-time basis as a consultant.

Mr Bogg said, “In my 43 years at Bright Steels I have worked with, and for, some good people. In the early years I was working on most jobs within the factory, before moving into the die shop which I enjoyed the most.

“In retirement I intent to spend more time on my hobbies – that is, when I get through the list of jobs waiting for me to do at home!”

Philip Jackson, Managing Director paid tribute to Peter saying, “Peter’s technical knowledge and that of our production processing is so valued that we are delighted he is to be retaining on a part-time basis as a quality consultant – ensuring that his expertise is not lost to the business and can be further passed on to the next generation of staff at Bright Steels Limited.”

Pictured with Peter Bogg (right) is Chairman, Paul Chouler (left).

The Tube & Wire Exhibition 2016

Bright Steels Limited would like to thank all of our customers, suppliers and friends who visited our stand during the Tube & Wire Exhibition held in Dusseldorf from 4th to 8th April 2016.

This was our fifth attendance at this exhibition and the busiest to date with more visitors to our stand than in past years.

Bright Steels Limited host a joint stand with our European Partner for the distribution of freecutting steels, PKS GmbH, Peter Kördell Stahlhandel who are located in Mettmann, Germany.

New warehouse racking

To improve the efficiency of warehouse operations and the safe storage of bundles in the main bright bar warehouse, Bright Steels Limited have replaced floor standing bundle pens with new cantilever racking .

This provides 840 tonnes of additional storage capacity and ensures that all bundle storage in the company’s two bright bar warehouses is now provided with cantilever racking.

Electric Vehicles

Bright Steels Limited have acquired two electric vehicles for use in the movement of products in the main production works. A tow tractor and industrial platform trailer with a total payload of 8000 kgs will transport steel bundles from pre-processing operations to our draw benches. A 4-wheel-electric-counterbalance forklift has a lifting capacity of 3000 kgs and will transport coil raw materials to one of our in-line coil drawing machines.

Apprentice Appointments

Bright Steels Limited are delighted to announce the appointment of Jake Newsome and Chris Cook.

Jake joins as apprentice mechanical engineer and Chris as apprentice electrician.

We welcome them to our company and wish them a successful career.

New remote controlled transporter makes light work of heavy loads

Bright Steels Limited have installed a heavy duty electric platform transporter to carry completed orders from the preparation to the despatch area, reducing the use of lift trucks in the finished stock warehouse. It runs on a 38-metre-long dedicated rail track at the side of the warehouse, and incorporates flanged wheels and pressure-sensitive buffers to ensure safe operation.

The equipment has a load-bearing deck measuring 4000mm x 1200mm with supports that hold loads securely in place and is controlled by an operator with a wireless hand-set. It is driven by twin power systems powered by a 24V high-capacity battery and linked to a pair of drive wheels directly coupled to hydraulic motors.

Bright Steels gets new side loader fleet

In conjunction with the investment of new racking into our main bright bar warehouse Bright Steels Limited have updated their fleet of side loaders used for the picking of bundles from stock.

Three LP gas multidirectional 4-way lift trucks made to our unique requirements with extending forks, lift height of 5500mm and lift capacity of 4000 kgs are now operational.

© Bright Steels Ltd 2016 Website by: CLOUD NINE DESIGN

© Bright Steels Ltd 2016 Website by: CLOUD NINE DESIGN